Materials Recycling Technologies

MacDermid Envio has a deep understanding of the pressures that are placed upon our customers around the world. In fact, “Enabling Sustainability” is one of the core principles of MacDermid Envio's corporate culture. Enabling Sustainability, within MacDermid Envio is also a core tenet of our Research & Development activities. The vast majority of our technical innovations must offer significant environmental benefits before being released to the market. These sustainability advantages may include; reduced energy consumed, reduced concentrations, the ability to recover and re-use materials from waste streams, reduced rinsing and water consumption, elimination of SVHC and other aspects that positively reduce the environmental footprint of our customers. The acquisition of Chemtech Systems strengthens our commitment to providing leading equipment solutions enabling our customers to reduce their environmental footprint by Controlling material used during the production process, Recovering materials that normally go to waste and Re-using recovered materials in the production process. These production-proven systems not only reduce our customer’s environmental impact but offer significant cost savings.

Purify

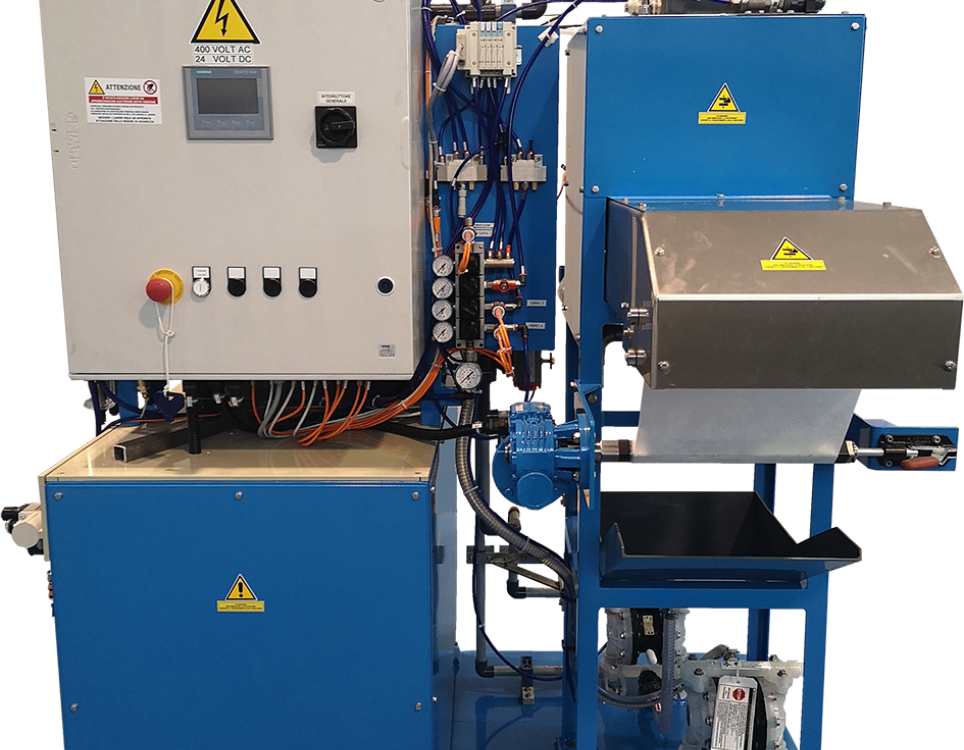

Purification equipment ensures consistent quality.

Our purification equipment employs state of the art designs and builds quality to effectively remove impurities. This automatically yields increased longevity of the chemistry, resulting in higher productivity due to improved bath consistency.

Our equipment units are built to remove organics, unwanted metals, calcium salts, and sodium salts, all of which can slow down plating rates and eventually lead to marginal performance. We offer equipment to purify nickel baths, trivalent chrome baths, zinc & zinc-nickel baths, as well as passivate purification.

Recycle

Recycle and reclaim your Copper, Nickel, Chrome, and Palladium from processes and rinse waters.

Our metals recycling know-how has resulted in a market leadership position in reclaiming metals from plating rinse water. Our equipment can reclaim Copper, Nickel or Chrome and directly return these metals to your production processes, with no loss of performance. When combined with our water management technologies, we can significantly reduce the amount of freshwater needed for efficient rinsing. Recycle units also significantly reduces the amount of metal going into wastewater treatment systems thus significantly reducing the cost of waste disposal.

Our recycling equipment is the market-leading metals recovery choice for the surface finishing industry, providing an exceptional return on investment and unparalleled benefits for environmental sustainability.

Sustain

Steady State equipment for continuous production operation and process control.

Maintaining processes under optimum operating conditions is critical for both productivity and waste minimization. Optimizing chemical concentrations ensures production waste and rejects are minimized and rinse waters handle only the waste necessary for optimum production.

Equipment designed to continuously monitor and control key process parameters with direct benefits for process consistency and waste minimization.

Our ‘Steady State’ controllers have been specially developed to take care of control and replenishment of processes such as Electroless Nickel, where regular monitoring and dosing is essential to consistent operation. Our ‘Steady State’ approach can be adapted to other processes too, offering not only enhanced operational consistency but reduced waste created by excessive or overdosed chemical maintenance.

Sustaining processes within their design parameters ensure consistent operation, reduced operating cost, reduced rejects, and minimal waste generation.

Comply

MacDermid Envio, Chemtech and TrueLogic provide equipment solutions and production monitoring systems to help our customers achieve regulatory and environmental compliance of water quality objectives. Together we offer multiple technologies to remove contaminants allowing a significant amount of your process water to be reclaimed and returned to your plating lines.